How Artificial Intelligence Electronics Are Building Your Future .

Have you ever wondered about artificial intelligence electronics? It sounds super cool, right? It’s like when robots design the tiny brains that make your favorite video game console or smartphone work. Here is the one-sentence answer: Artificial intelligence electronics is the use of smart computer programs to design, build, and improve the electronic parts—like microchips—that power all our modern technology.

Check our post on: AI role in Green Automotive Technology: How Smart Cars are Saving Our Planet

What Is Artificial Intelligence Electronics? Lets dive in!

You already know that artificial intelligence (AI) means smart computer programs that can learn things and solve problems, kind of like your brain. But what happens when you combine that amazing smartness with electronics?

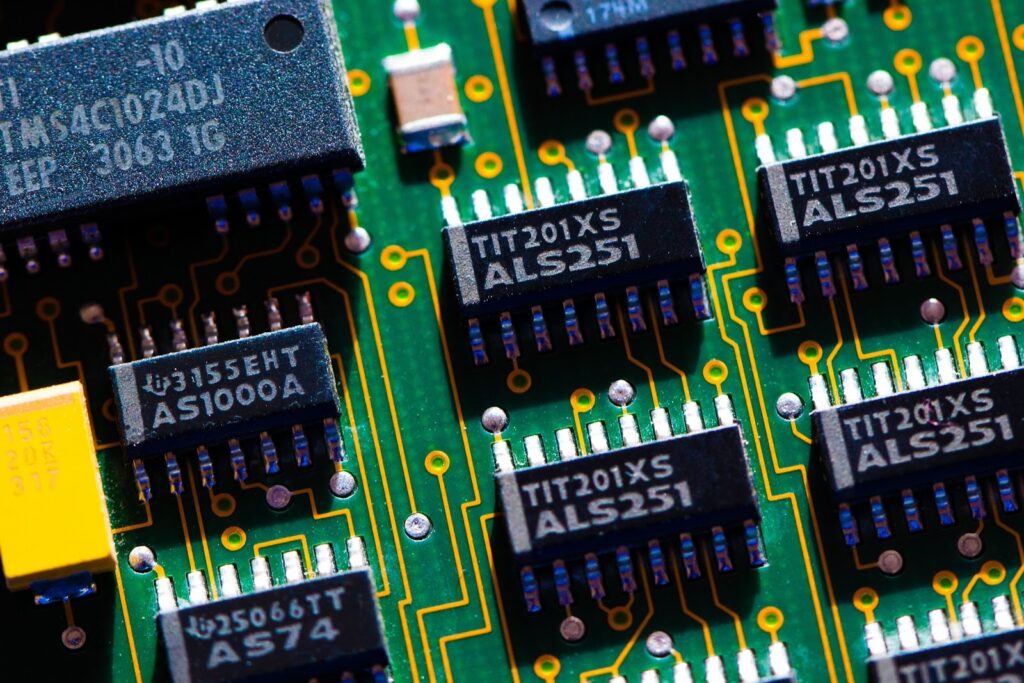

Electronics are the tiny components—like resistors, capacitors, and transistors—that control the flow of electricity. When you put billions of these tiny things together, they form a microchip.

So, artificial intelligence electronics is a phrase that describes two important things happening in the tech world:

- AI for Electronics: This is when we use AI to design, test, and manufacture microchips and electronic systems. This is the biggest part of the story, covering everything from design automation to factory robots.

- AI in Electronics: This describes the special chips (like Neural Processing Units, or NPUs) that are built specifically to run AI programs super fast, often right inside your phone or laptop. These are vital for smart device optimization.

It’s truly a huge, dynamic landscape! AI is used to make the chips, and the chips are used to run AI. It’s a wonderful feedback loop that keeps making technology better and better.

The Complexity Crisis: Why AI Became Necessary

Why did we suddenly need AI for this job? Well, chips have become too complicated for humans to handle alone.

Imagine a city map. A computer chip is like a city made of wires. Now, imagine this city is smaller than your fingernail and has more wires and components than there are people on Earth! That’s how big the design space is.

Before AI, engineers used tools called Electronic Design Automation (EDA) software. EDA tools help you draw and test the chip design. They were good, but slow. They were like using an old map to navigate a brand-new, expanding city.

When a designer tries to fit a billion transistors onto a tiny space, they have infinite choices for where to put them. Humans can only check a few thousand. This causes frustration because the best possible design might be missed.

Did You Know?

The number of possible designs for a modern microchip is so huge that it actually exceeds the number of atoms in the entire known universe! No human brain could ever solve that puzzle alone, which is why AI is our helper.

The rise of AI gave engineers a powerful new stimulant. AI uses a type of learning called Reinforcement Learning. It learns by trying things out and getting a “reward” when it finds a better solution, similar to how we train a dog with a treat! It can search billions of possible layouts in hours, finding designs humans never even thought of. This ability is what we call AI microchip design.

How Does Artificial Intelligence Electronics Work? Step by Step

The process of using AI to create electronic components, especially microchips, can be broken down into three main phases. We will look at design, manufacturing, and performance.

AI in Electronic Design Automation (EDA)

This is where the magic starts. Before any chip is built, it must be designed using specialized software. AI is now deeply woven into this process, cutting down design time from weeks to just hours. This is a massive inducement for innovation.

The 5 Steps of AI Microchip Design

1. Defining the Goal (The Problem):

- Human Job: Engineers tell the AI exactly what the new chip needs to do. For instance, “Design a chip that uses very little power but runs the screen on my smartphone.”

- The AI’s Role: The AI takes these human requirements—like low power and high speed—and uses them as its “reward” goal.

2. Design Space Exploration (The Hunt):

- Human Job: Previously, engineers would manually test different layouts. This was very slow.

- The AI’s Role: The AI uses Reinforcement Learning to explore billions of layouts automatically. It’s like having a super-fast helper that tries out every possible maze path instantly. It’s searching for the optimal power, performance, and area (PPA) combination. This AI microchip design is what Synopsys, a major industry leader, focuses on. You can read more about this on the Synopsys on AI Chip Design page.

Check our post on: Super-Smart Personal AI Tool for Growth and Networking

3. Placement and Routing (Laying the Wires):

- The Problem: The most difficult step is deciding where to put the tiny logic gates and how to connect them with millions of wires. If the wires are too long, the chip will be slow and waste power.

- The AI’s Role: The AI uses algorithms to calculate the shortest and most efficient placement for every single component. It figures out the perfect “route” for the data to travel, which is often a layout that looks totally weird and unintuitive to human eyes. This is a huge gain in efficiency.

4. Verification and Testing (Checking the Work):

- The Problem: Finding tiny flaws in a billion-component chip is nearly impossible for a human team. A single missed error can cost millions of dollars and lead to a defective product.

- The AI’s Role: AI runs massive simulations—digital versions of the chip—to test how they will behave under every possible condition, like being too hot or receiving too much power. It spots tiny timing or connectivity errors that humans would miss, saving time and avoiding a huge headache later on.

5. Design Reuse and Migration (Learning from Experience):

- The AI’s Role: Once an AI finds a perfect design for one part, it remembers that “learning.” It can quickly apply that solution to a new, different chip design. This is called knowledge transfer. It makes moving old designs to newer, smaller manufacturing technologies (called process nodes) much faster.

Simple Activity: The Wiring Challenge

Want to see how complex this is? Draw a 5×5 grid. Place 10 “start” dots and 10 “end” dots on the grid. Now, try to connect all 10 start dots to their corresponding end dots using single lines that never cross. You will quickly feel the exasperation that engineers used to feel! Now imagine doing that with a billion dots. That’s the challenge that AI solves for us!

AI in Manufacturing (Automated Quality Control)

Once the design is finished, the chip has to be manufactured in huge, super-clean factories called fabs. This is where AI moves from being a designer to being a vigilant supervisor using automated quality control.

Comparison: Human vs. AI Quality Checkers

| Feature | Traditional Human Inspection | AI-Powered Quality Control (QC) |

| Speed | Slow, limited to a few samples per hour. | Extremely fast; checks thousands of components per minute. |

| Consistency | Varies depending on human fatigue, shift changes, or distraction. | Perfect consistency; never gets tired, never misses a pattern. |

| Defect Size | Hard to spot defects smaller than the width of a human hair. | Can spot flaws that are just a few nanometers wide (incredibly small!). |

| Cost | High labor costs, plus the cost of missing a defect. | Lower operating cost once systems are set up. |

How does AI do this? It uses computer vision. This is where cameras take millions of pictures of the chips as they are being made. The AI trains itself by looking at good chips (the “right” ones) and bad chips (the “wrong” ones).

When a new chip comes down the line, the AI scans it instantly and looks for any deviation. If it sees a tiny scratch, a missing layer, or a strange pattern, it flags the part immediately. This prevents a bad chip from ever leaving the factory. It’s a great example of semiconductor industry AI in action, guaranteeing higher product quality and reliability.

Did You Know?

The global Electronic Design Automation (EDA) industry, which relies heavily on AI tools, is expected to be worth over $22 billion by 2030! That’s a huge surge in motivation for companies to keep using AI. You can find this data reported by Semiconductor Engineering on EDA Market Data.

AI in End-User Devices (Smart Device Optimization)

AI doesn’t just build the chips; it also lives inside them! These specialized chips, often called NPUs (Neural Processing Units), are electronic parts created specifically to make AI algorithms run efficiently on your personal devices. This is key for smart device optimization.

When you use features like:

- Real-time language translation on your phone.

- Instantly blurring the background in a video call.

- Taking incredible photos in low light using computational photography.

These tasks use tons of math, but they need to be done instantly without draining your battery. The NPU chip, designed by AI itself, handles these jobs perfectly. It uses less power than the main processor, which keeps your phone fast and cool. This advancement creates huge stimulation for new app development!

Research groups are constantly improving this. For example, the Georgia Tech AI Optimization Research group focuses on using AI to manage and optimize these complex systems, making sure everything runs smoothly and efficiently.

Examples You Can Try Today

We talked about how AI is transforming electronics. Let’s look at some real-life, exciting examples of how this is already changing our world.

- Next-Generation Wireless Chips:

- AI is designing chips for 6G wireless communication right now. Researchers found that AI can create electromagnetic structures that look “random-shaped” to a person but offer performance that was “previously unachievable.” This is truly shocking and shows that AI can push past human intuition. It’s an inspiration for engineers everywhere! This breakthrough proves the huge benefits AI brings to microchip design, as described in this Innovation News Network on Microchip Benefits.

- Self-Driving Cars:

- Cars today are packed with sensors—cameras, radar, lidar. Processing all that information instantly to decide whether to brake or turn takes massive electronic power. AI designs the dedicated chips (ASICs) that handle this real-time computing. This makes the electronics trustworthy and safe, which is a huge focus for every major auto company.

- Medical Wearables:

- Think about a tiny health tracker that monitors your heart rhythm for weeks on end. It needs to be super small and use almost no battery. AI designs the chip layout to optimize for power efficiency and size. This is perfect smart device optimization, allowing doctors to get continuous, accurate data without needing huge batteries.

Did You Know?

AI can reduce the time it takes to complete a chip design process from several months down to just a few hours. That’s a reduction in development time of over 99%! This incredible speed is the biggest inducement for companies to adopt the technology.

Personal take on the topic – My Journey into AI Electronics

I remember when I first started researching this topic. It reminds me of the first time I saw a movie where a computer designed itself. I thought it was science fiction, but it’s actually happening!

Here’s what surprised me: the sheer scale of the complexity. When I learned that a chip design might have more possibilities than atoms in the universe, I honestly thought that was wrong. It gave me a huge headache trying to grasp that level of detail. But then I realized that the whole point of AI is to tackle problems that are too big for us. AI isn’t replacing us; it’s extending our capabilities, which is a wonderful inspiration.

One time, I saw a demonstration of an AI performing automated quality control on a manufacturing line. The factory floor was loud and huge, but the AI system was silent and precise. It could spot microscopic flaws in a silicon wafer that a human inspector would never catch, even with a magnifying glass. The human inspector’s job wasn’t gone; instead, they were supervising the AI, making sure the system was right. Their job became less about tedious checking and more about complex problem-solving. It truly made their work more interesting.

We encourage you to keep exploring this amazing field and maybe even start learning how to code some simple AI yourself. The future of the semiconductor industry AI depends on young minds like yours! Leave a comment below and tell us which part of the AI electronics journey you found the most surprising!

One thought on “How Artificial Intelligence Electronics Are Building Your Future .”